MIM (Metal Injection Molding) combines the technologies of thermoplastic injection molding and powder metallurgy to produce complex-shaped, high density, high performance metal parts.

Not only the external dimension tolerance but internal dimension tolerance will be guaranteed. An internal helical gear is one of the examples.

These gears were traditionally only possible by machining or by special dedicated machine, which is not able to produce small size gears and this is the reason the customer use plastic gears.

However, MIM realises the mass production of such small special gears, and now it is commonly employed for such gears mass production.

1. Best applied to small parts (typically less than 100 grams)

2. Offers lower cost solution

3. Improved mechanical properties

MIM mainly materials

Material System | Material composition | Typical applications |

Low alloy steel | Fe-2Ni, Fe-8Ni | Automobile, Machinery, ect |

Stainless steel | 316L, 17-4PH, 420, 440C | Medical equipment, Clocks, ect |

Carbide | WC-Co | Various tools, Watches, ect |

Ceramic | Al 2O3, ZrO2, SiO2 | IT electronics, Daily necessities |

Heavy Alloys | W-Ni-Fe, W-Ni-Cu, W-Cu | Arms industry, communications |

Titanium | Ti, Ti-6Al-4V | Medical and military structural parts |

Magnetic Materials | Fe, NdFeB, SmCo5, Fe-Si | Magnetic properties of various components |

Tool steel | CrMo4, M2 | Tools |

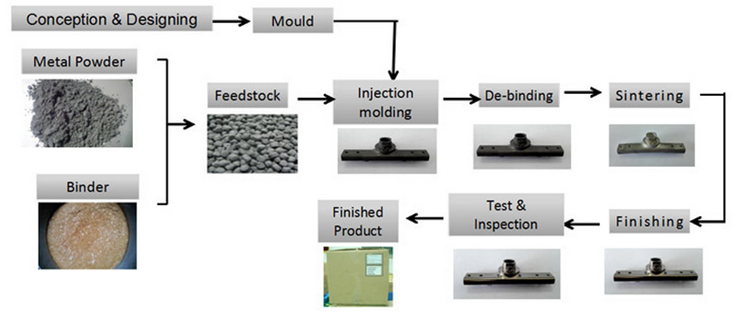

How MIM Works

The MIM process combines the design flexibility of plastic injection molding with the strength and integrity of wronght metals to offer cost effective solutions for highly complex part geometries.

The MIM process is typically explained as four unique processing steps (compounding, molding, debinding and sintering) to produce a final part that may or may not need final finishing operations

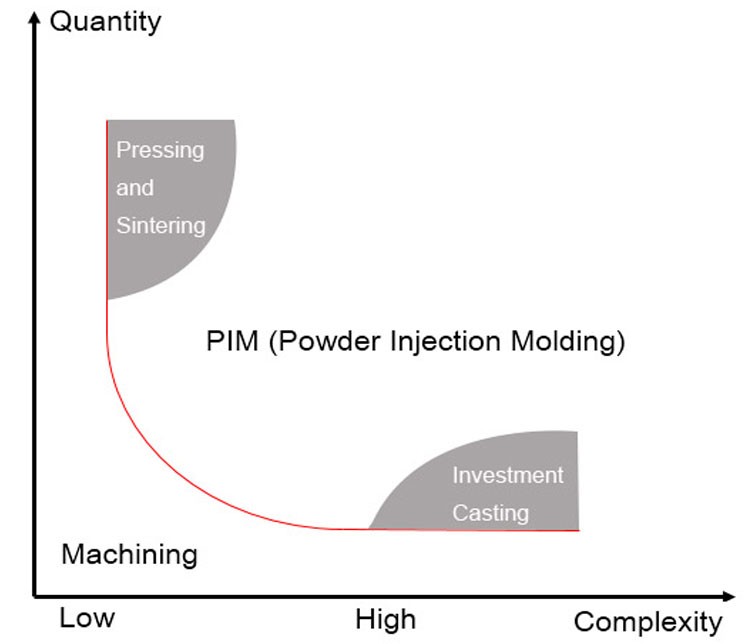

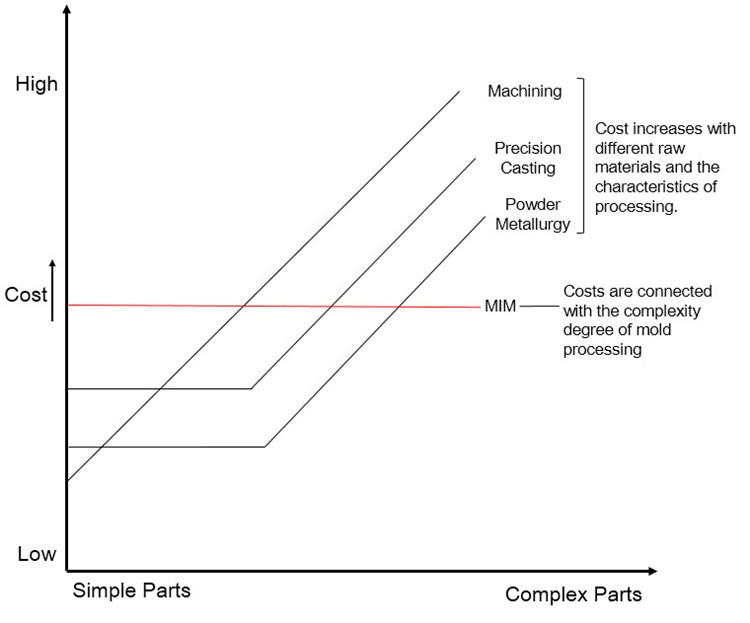

Comparison between MIM and Traditional Machining

Comparison between MIM and Other Processes

Parameter | MIM | CONVENTIONAL PM | MACHINING | INVESTMENT CASTING |

Density | 98% | 88% | 100% | 98% |

Tensile Strength | High | Low | High | High |

Elongation | High | Low | High | High |

Hardness | High | Low | High | High |

Min. Wall Thickness | 0.5 mm | 1 mm | 0.5 mm | 2 mm |

Complexity | High | Low | High | Medium |

Surface Finish | High | Medium | High | Medium |

Production Volumes | High | High | Low | Medium |

Range of Materials | High | High | High | Medium-High |

Cost | Medium | Low | High | Medium

|

With an X-ray CT device, it is possible to obtain complete 3-dimensional measurement data, including the inside of the gear.

This inspection and evaluation system is indispensable for providing customers with MIM that is even finer, more precise, and of higher quality.

There are many things that can be achieved in microgear production with this system, but the first is that it enables a higher level of quality assurance.

Besides pitch error, tooth thickness, tooth type / tooth muscle error, tooth surface error, etc.,grade evaluation (corresponding to JIS) for micro gears of rice grain size or smaller is also possible.

Our cutting-edge quality control assurance system supports our micro gear quality in time, non-destructively. Any certifications of gear standard will be provided with our component by request.

If you have any micro gear design given up for the serial production as they're difficult to produce with other manufacturing methods, please contact us with the drawings.

Profeession and reliability; Our advantages are multiple available technologies, strong quality assurance, and good at project & supply chain management.

a. With our partners we perform APQP at an early stage in each project.

b. Our factory must fully understand the quality concerns from customers and implement product & process quality requirements.

c. Our quality professionals who perform patrol inspection in our factories.We perform final inspection before the goods are packed.

d. We have 3rd party inspectors who perform final audit checks on the packed goods prior to dispatch from China.

We enjoy to grow up together with all our clients whatever big or small. You will become bigger and bigger to be with us.

The powder metal metallurgy process provides a host of advantages over competing metalworking technologies. These all add up to part-to-part uniformity for improved product quality, shape and material flexibility, application versatility, and cost effectiveness.

Save money - with manufacturer direct pricing

Save time - with experienced team to get project done

Lead the industry - with the most cutting-edge products

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.